WALTHAM, Mass,– AeroShield Materials, an MIT spin out developing cutting-edge technology for energy efficiency applications in the built environment, announced today the opening of their new manufacturing facility in Waltham, Massachusetts and the close of $5M in additional funding with participation from existing investors Massachusetts Clean Energy Center and MassVentures as well as new investor MassMutual Ventures. The funding will support AeroShield in scaling its business by enabling the company to expand its team to more than 30 employees in the 12,000 square-foot facility where it plans to manufacture full-sized products, including double pane windows.

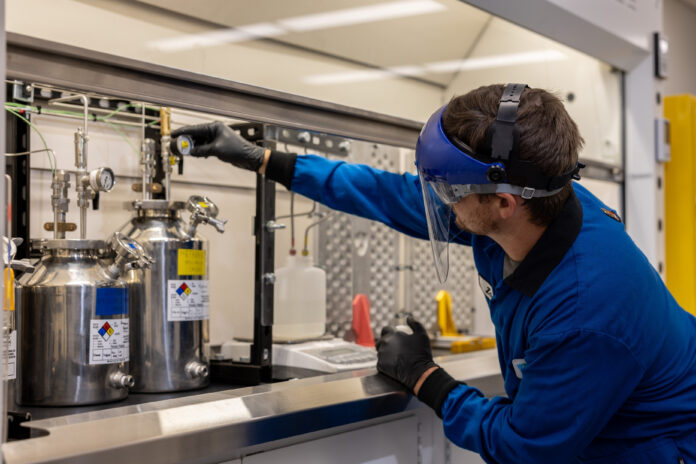

AeroShield’s breakthrough transparent silica aerogel sheets are some of the most insulating materials ever created and can be added inside double-pane windows and doors to improve energy performance by up to 65%. The facility in Waltham will significantly expand the company’s capabilities with cutting-edge aerogel R&D labs, manufacturing equipment, assembly lines, and testing equipment.

“This facility represents an inflection point in AeroShield’s journey. This is where we will turn our scientific breakthrough into the first certified transparent aerogel windows and begin saving residents billions in heating and cooling costs,” said AeroShield CEO Dr. Elise Strobach. “Our pilot facility will supply window and door manufacturers as we launch our first products and also serve as our R&D headquarters as we develop the next generation of energy- efficient products using transparent aerogels.”

According to the US Department of Energy, window inefficiencies are responsible for up to 30% of a homeowners’ heating and cooling bills, and Americans lose $40B per year of energy through their windows. High performance windows like those produced by AeroShield can save homeowners money, reduce carbon emissions, and improve resiliency during extreme temperature events. Just 4mm of AeroShield’s clear material inside a standard double pane window outperforms triple pane windows at double pane thickness and weight, reducing the cost of high-performance windows while still allowing consumers to choose from existing window designs.

“AeroShield represents the type of innovation and growth that is making Massachusetts the climatetech hub for the world,” said Dr. Emily Reichert, CEO of the Massachusetts Clean Energy Center. “MassCEC exists to help propel companies like this through the training, guidance, grants, and investment they need to go from lab to market. AeroShield’s new manufacturing center in Waltham is now part of our growing climate corridor, helping Massachusetts show the world what’s possible.”

The culmination of years of research at MIT by Dr. Strobach, AeroShield was founded to enable our homes to be more sustainable and efficient using the world’s most transparent silica aerogels. Silica aerogels are composed of more than 95% air trapped inside nanopores, making them one of the lightest and most insulating solids ever created. While aerogels have been used at institutions like NASA for decades, they are generally opaque and tinted. AeroShield’s patented material is more transparent than glass, enabling new high-value use cases for the materials.

“AeroShield Materials is a perfect example of our thesis of supporting founders addressing significant climate problems that have historically been underfunded,” said Karl Beinkampen, Venture Partner at MassMutual Ventures. “In addition to reducing the carbon emissions associated with heating and cooling the built environment, the company has created an elegant solution which at scale provides a compelling economic proposition to the end-user. Installing AeroShield products will simply be a better financial decision.”

While R&D is currently focused on residential windows and doors, the material has a wide range of applications, such as commercial windows, grocery store freezer doors, ovens, electric vehicle windows, and solar thermal energy.

“MassVentures has been a long-time supporter of AeroShield through equity investments from our SSBCI Diverse Founders and non-dilutive grants like START,” said Charlie Hipwood, CEO of Mass-Ventures. “This new facility is the latest example of the team delivering on their mission to decarbonize the built environment.”