HOUSTON — Starlab Space LLC has entered into a partnership with Auxilium Biotechnologies to bring orbital 3D bioprinting and biofabrication capabilities to the planned Starlab commercial space station, expanding opportunities for life sciences research and manufacturing in microgravity.

Under the agreement, Auxilium will deploy its AMP-1 3D bioprinting platform aboard Starlab to support research and development in regenerative medicine, implantable medical devices, and complex tissue engineering. The companies said the collaboration is intended to accelerate the transition from experimental biology to scalable manufacturing in low Earth orbit.

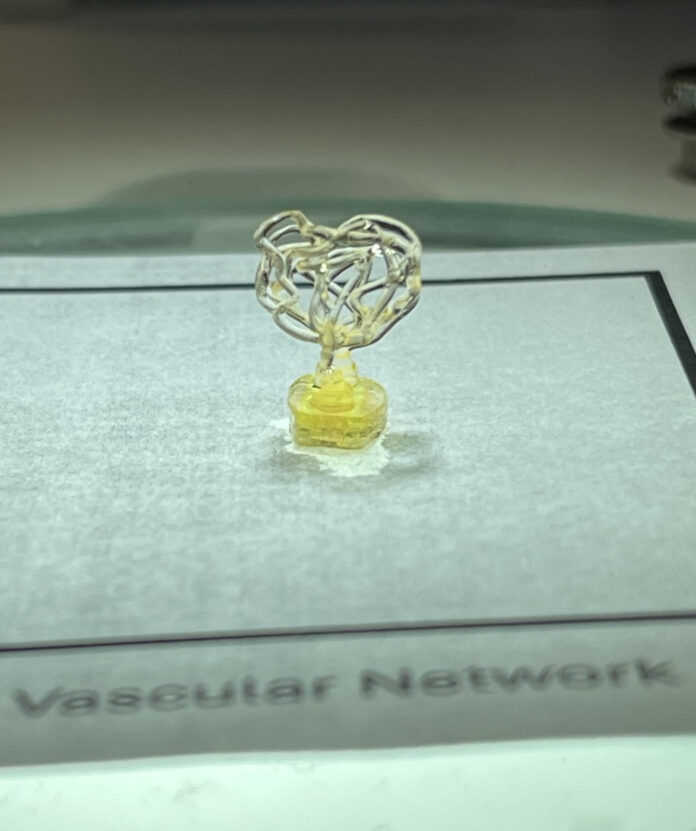

Auxilium has previously demonstrated the potential of microgravity biomanufacturing. In November 2024, the company successfully produced tiny, functional blood vessels aboard the International Space Station using its AMP-1 system. The vessels, with wall thicknesses roughly the width of a human hair, were produced in under an hour, a process that typically requires more time, materials, and complexity under Earth’s gravity. The work highlighted the potential for on-demand tissue production to support astronaut health during long-duration missions to the Moon and Mars, while also informing future therapies on Earth.

“3D printing in microgravity enables tissue architectures and material properties not achievable under standard 1g manufacturing,” said Isac Lazarovits, director of engineering at Auxilium. “This biomanufacturing facility on board the future Starlab space station will expand access to low Earth orbit, lower barriers for industry and academia, and enable high-impact research and manufacturing that will benefit Earth.”

Starlab said the partnership reflects its broader strategy to build a robust ecosystem for life sciences research and biomanufacturing in orbit. Microgravity environments can enable advances that are difficult or impossible on Earth, including improved protein crystallization for drug development, three-dimensional cell growth and disease modeling that more closely mirrors human biology, and advanced stem cell research with potential applications in neurological and metabolic diseases.

“This partnership demonstrates Starlab’s commitment to fostering innovation in life sciences,” said Marshall Smith, chief executive officer of Starlab. “By providing companies like Auxilium with the infrastructure to advance biomanufacturing in microgravity, we’re creating pathways for breakthrough therapies that will improve lives on Earth.”

Starlab’s commercial space station is designed around a market-driven model intended to reduce cost, complexity, and risk for researchers and commercial partners. The company said its single-launch, no-assembly-required design is expected to allow certification and operations to begin within weeks of launch, minimizing delays for payload customers. Through joint venture partners, researchers can conduct work on the International Space Station today, with plans for a smooth transition to Starlab as it becomes operational.