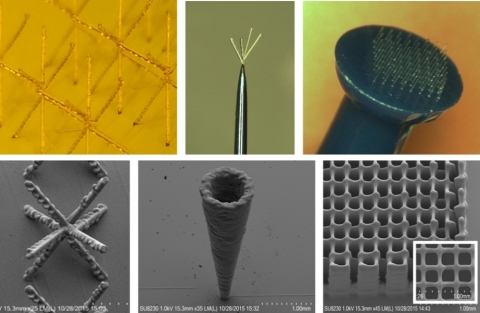

ALBUQUERQUE, N.M.– Optomec, an established leader in Additive Manufacturing solutions for 3D Metal Printing and 3D Printed Electronics, has received new patents covering the use of Aerosol Jet for producing 3-dimensional micro-structures. This novel capability enables the production of miniature elements with a resolution down to 15 micron features – approximately 1/5 the width of a human hair, and smaller than the resolution of the human eye. The capability has been demonstrated for a range of materials, including polymers, metals and composite structures. These new grants are the latest in an IP portfolio that totals more than 75 patents issued, with global protection including the US and key markets across Asia and Europe.

The new 3D micro-printing patents present a method for fabricating three-dimensional structures using in-situ heating or UV illumination to modify the properties of aerosol droplets as they are jetted onto a target surface. In the case of the UV embodiment, light at least partially cures photopolymer droplets, or alternatively causes droplets of solvent-based nanoparticle dispersions to rapidly dry in-flight, and the resulting increased viscosity of the aerosol droplets facilitates the formation of free-standing 3D shapes. Lateral resolutions of 15um have been achieved, with layer thicknesses of 100 nanometers and aspect ratios of >100X for structure heights measured in millimeters.

Dr. Michael Renn, Chief Technology Officer, is the inventor on these new patents, and has more than 50 patents to his credit in total. “Optomec continues to invest heavily in its core technology, seeking to extend the already broad range of applications for its Aerosol Jet solution,” said Dr. Renn. “The capability demonstrated with our 3D Printed Micro-structures work is already seeing potential applications in Semiconductor Packaging and Medical Device markets.”